EMS

Electronics

as a service

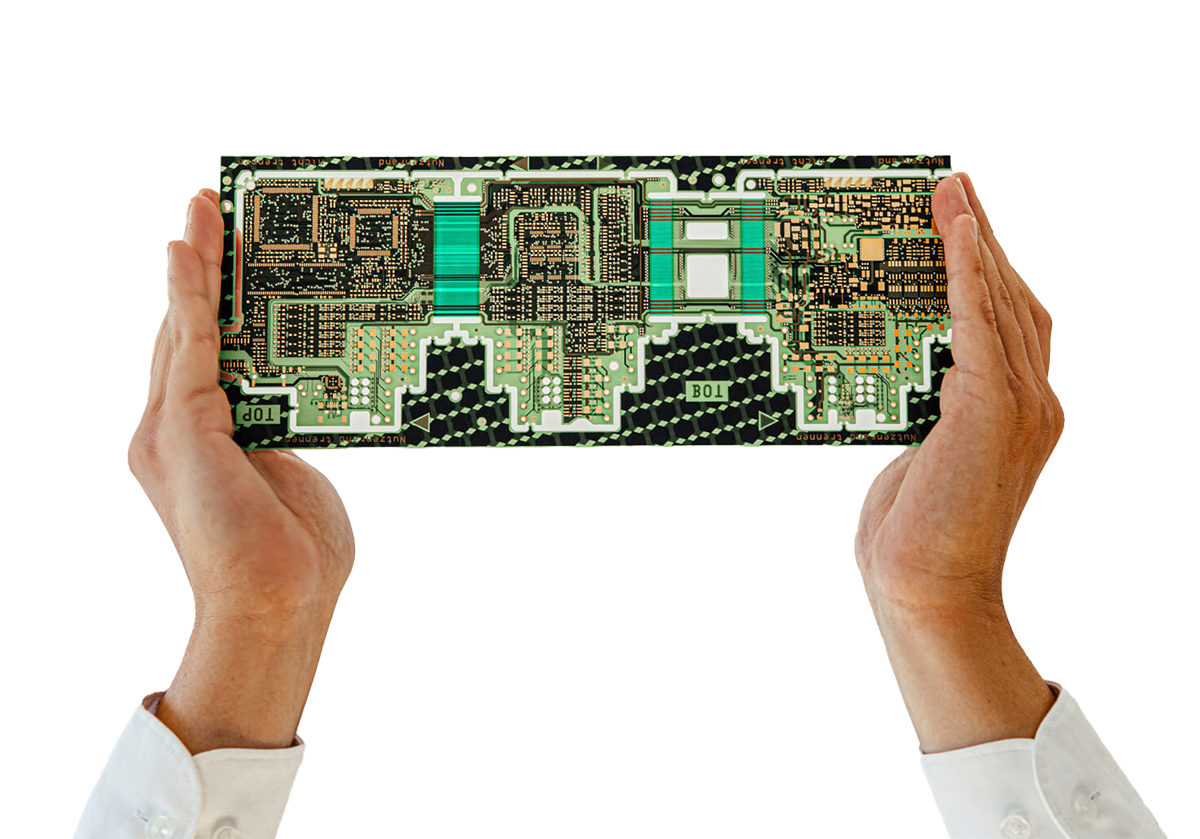

Printed circuit boards are the heart and the bond between electronics and technology.

Printed circuit boards are responsible for connecting different parts and components together to create strong and functional products. They are the invisible heroes working in the background, but without whom nothing would work – the key to countless possibilities. Printed circuit boards turn dreams into reality by connecting the most incredible ideas.

Services at a glance

From initial consultation to delivery

Service spectrum

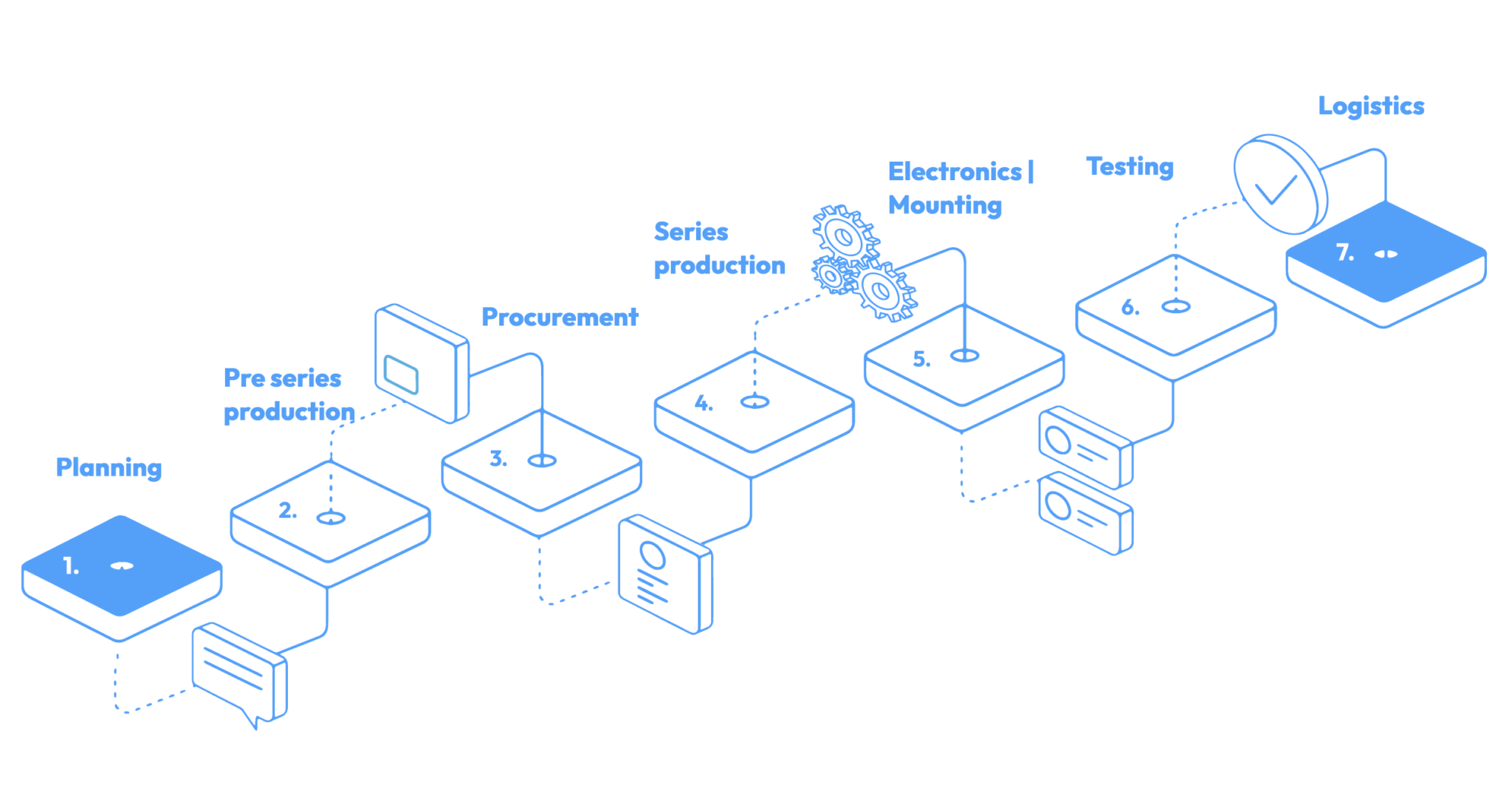

The process flow

Seamless service – from planning to logistics

1. Planning

Comprehensive advice

At wtronic, we support you with our comprehensive expertise. Whether you already have a finished product or a prototype that is not quite ready for series production, we will be happy to advise you with the extensive knowledge our experts have gathered over many years.

During the initial consultation many areas are covered. We check whether your schematics can be smoothly transferred into series production. In this context, we focus on the interoperability with current manufacturing technology to ensure that your design can also be implemented in series production. Another aspect covered are component consultations, during which not only the availability of selected components is examined, but eventual cost-efficient alternatives are explored.

Experts analyze whether the components are placed appropriately, and check possible improvements to help smooth out the transition to series production.

Alternatively, finalized designs, finished products or plans to implement a redesigned product are welcome, too. Maximum flexibility, as we’ve already emphasized to maximum effect.

In addition, we can offer prototyping and further development of your product, even if we are not the original developers. With your data, we build prototypes and pave the way for the next phase. You will receive valuable feedback from our experts, which you can incorporate into further development. Based on your tweaked design, small series or samples can be produced, depending on the individual needs of your project. With these iteration processes we endeavor to refine your product and ensure it meets the highest standards of quality and performance. Simply put, it helps to define a diamond in the rough.

With wtronic, you have a reliable partner who not only has expertise in series production, but has experience in the areas of consulting, prototype construction and continuous further development as well – perfect conditions to take your visions from the drawing board all the way to a successful product.

- Advice on process safety

- Advice on optimizing costs

2. Pilot production

We support you with development processes

Our experienced and committed staff is happy to help you implement your visions and ideas.

We optimize your production for you, with the assistance of external partner companies if required (PCB layouts, specifications, development of customized products, EMC measurements (CE certificate), prototypes, production transition). By adopting an agile approach to customer service, we endeavor to accompany you from design to production, from prototypes to series production, and beyond even that.

Pilot and small-batch production

Rush service and samples

Especially during development, it is vital that things move rather quickly. As a manufacturer with locations in northern Italy and Slovenia, we have the optimal range of locations to stay near our customers. This allows us to respond quickly to our customers’ needs and to flexibly manufacture, test and deliver electronic samples or pilot series until the product is ready for the market and regular production can proceed.

- Rush service for assemblies/assembly

- Sample and small-batch production

- Consulting for production-ready designs

- Certified according to ISO 9001:2015

3. Material purchasing

Component/material purchasing

and goods management

The comprehensive material purchasing service we offer covers a broad range, from printed circuit boards to highly complex processors as well as mechanical components, according to your specifications. With the wealth of experience gathered over the years, the materials management team is able to organize the punctual and reliable delivery of your goods at the best value for money. The way we approach component selection optimizes your costs. Since our production facilities and partners are close by, we offer high flexibility and speed.

Availability of relevant parts is examined at the enquiry stage, in the event of bottlenecks or if parts are obsolete, our team can propose substitutes. Alternatively, you can provide us with any materials you have already purchased for processing. Thanks to our efficient materials management we can handle secure storage or consignment stocks for you as well to ensure a safe and reliable supply chain.

„With our goods management system, in-depth market and component knowledge as well as our strong networks, we guarantee a smooth supply of materials for our customers.“

Florian Walchhofer, CEO

Printed circuit boards

In our services included is an extensive range of printed circuit boards, which includes all common printed circuit board technologies utilizing all currently available materials and all processing techniques. Thanks to our breadth of knowledge and a wide-ranging pool of experts, our daily purchasing activities are markedly flexible and highly independent. This results in good prices and timely deliveries.

4. Series production

Assembly and production

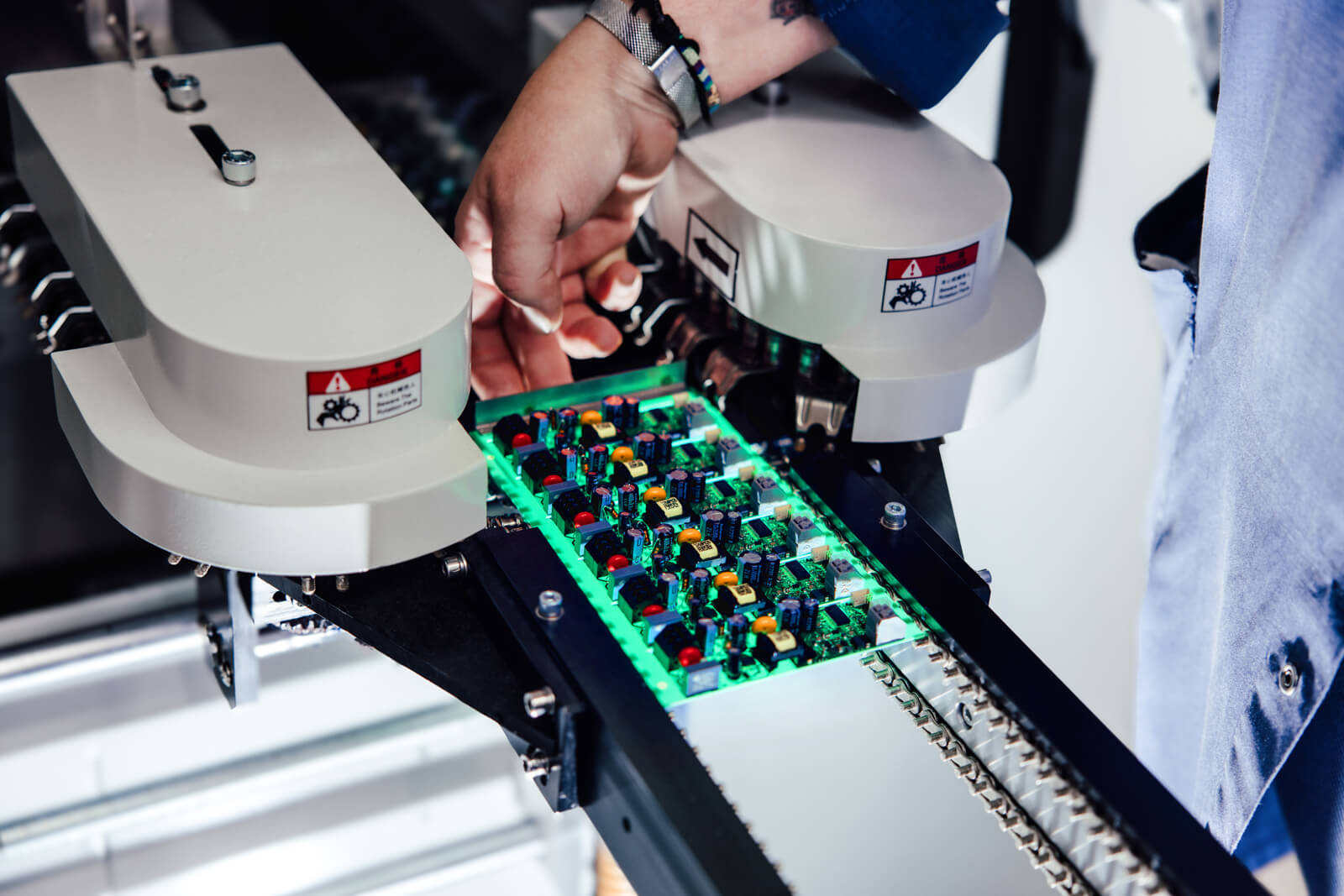

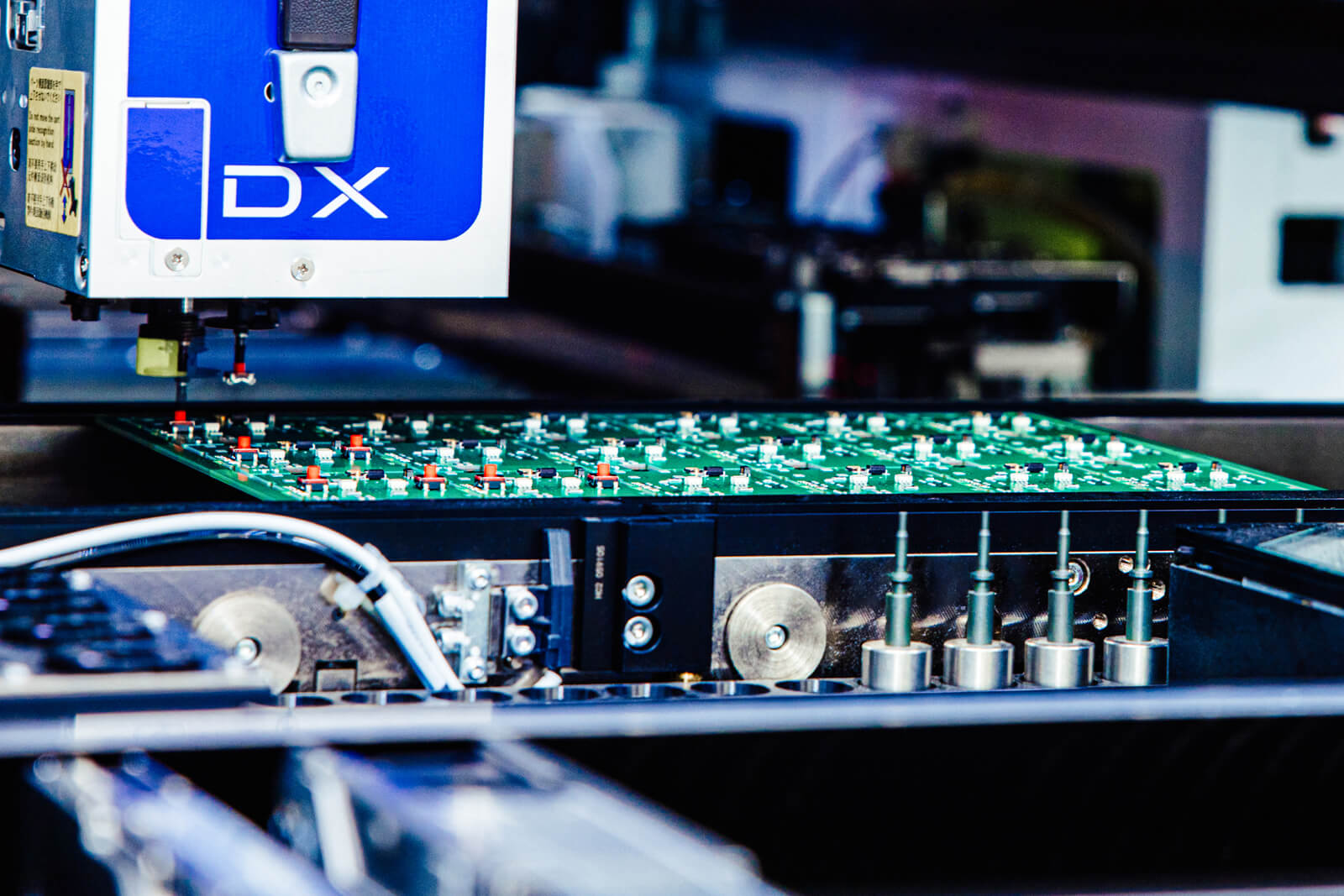

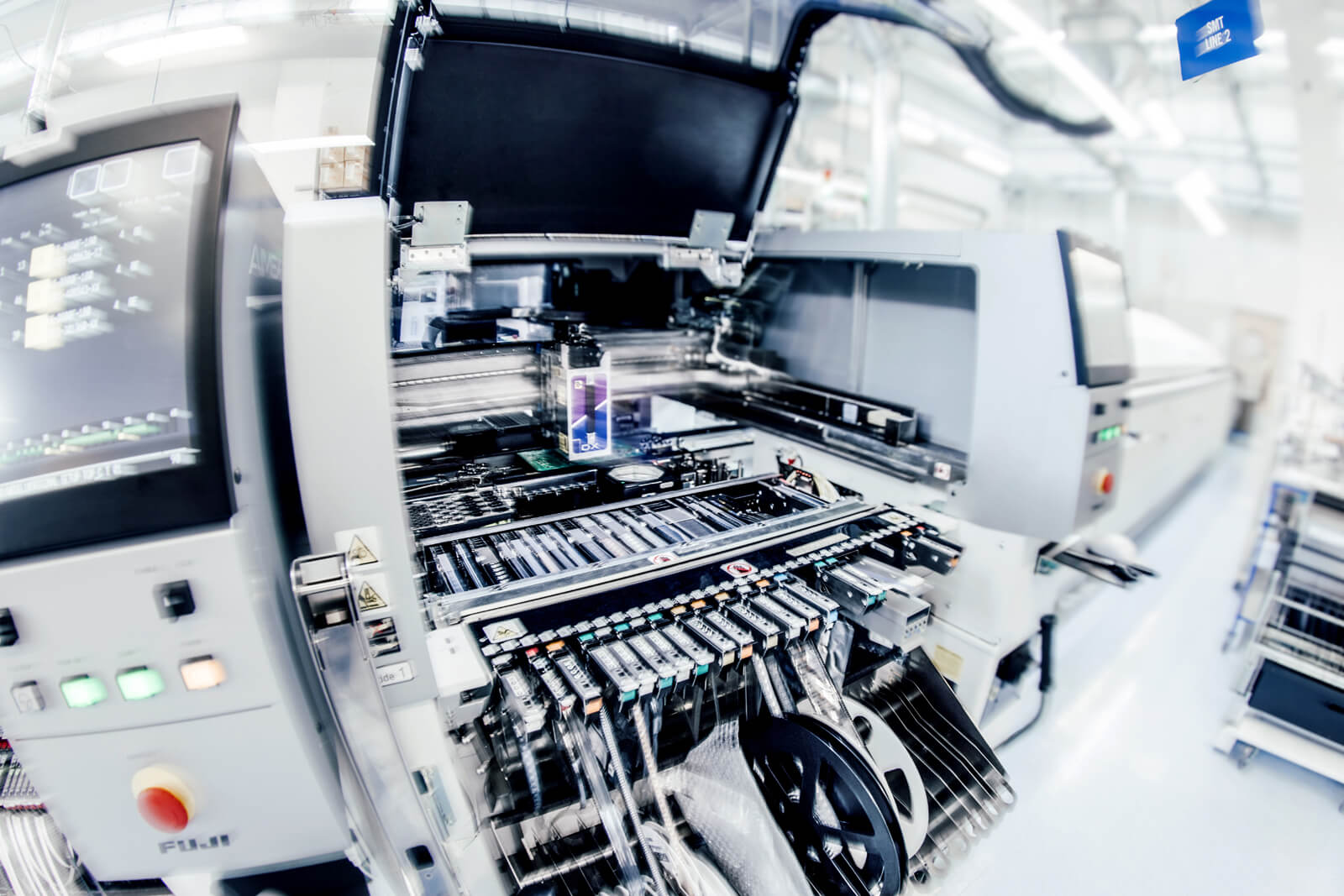

In the dynamic electronics market, continuous development in regard to miniaturization, speed and accuracy is essential.

wtronic is committed to providing intelligent solutions, implemented by highly motivated employees. Our state-of-the-art machinery enables us to implement customer requirements precisely and effectively, whether they are simple assembly processes or demanding high-tech applications.

With this approach, we always stay at the cutting edge of technology and ensure you achieve your goals.

We produce high-quality electronic products in our modern manufacturing sites in northern Italy and Slovenia. High technological standards, combined with sophisticated logistics, allow us to handle customer projects quickly and flexibly.

Our optimized production process enables us to keep to the agreed upon delivery date as well as providing flawless and consistent quality, regardless if it pertains to SMT, THT or mixed assembly.

Modern machinery and equipment as well as the commitment of our experienced employees ensure solutions are fiscally responsible and technologically sound.

We are THE partner for your electronic products.

Sneak peek into our production

Series production and supply chain integration

Reliable, economical and local

wtronic provides its customers with an extensive value chain integration. Due to this close cooperation, we achieve maximum flexibility and responsiveness to the needs of our customers. We guarantee punctual and smooth deliveries in perfect quality, even if the requirements of clients undergo rapid changes.

By utilizing customized production planning, wtronic enables our clients to minimize storage capacities and increase flexibility.

- Component procurement

- Traceability

- SMT line production with AOI, THT with solder wave/selective soldering

- Electrical testing

- Coating OR potting of electronic assemblies

- Complete units

- Certified according to ISO 9001:2015

Traceability

Accurate traceability for maximum

quality, tailor-made for your needs

At wtronic, the importance of traceability is well-known. Depending on the individual wishes of our customers, we adapt our traceability processes to observe the highest quality standards.

Included in our service is marking components by means of QR codes. Each individual component is given its own QR code which, when scanned, not only contains the information about the component itself, but the associated information from the manufacturer as well. Furthermore, the assemblies can be provided with serial numbers/QR codes/labels/lasers, depending on the customer’s requirements, to facilitate the assignment to production batches.

Whether you want each component to be marked individually or prefer marking the PCB as a whole, we can provide traceability adapted to your wishes.

This guarantees a transparent and reliable supply chain as well as optimized quality control for you, our valued customer. At wtronic, it is a point of pride to provide customers with the best of the best: Traceability, responsibility, and superb quality and commitment to ensuring your project launches without a hitch.

Our assembly services

from simple assembly processes to

complex high-tech applications

We offer assembly services for rigid and flexible PCBs with and without material purchasing.

Techniques such as THT and SMT are used by wtronic. In addition, protective coatings, potting and other special services are included in our service offers, too. Our machines are designed to manufacture assemblies individually or in panels. Of course, we assemble double-sided PCBs with the SMT and THT phases as well.

Convertible workstations for automatic and manual assembly afford us the means to efficiently adapt to diverse working conditions and respond rapidly without sacrificing flexibility.

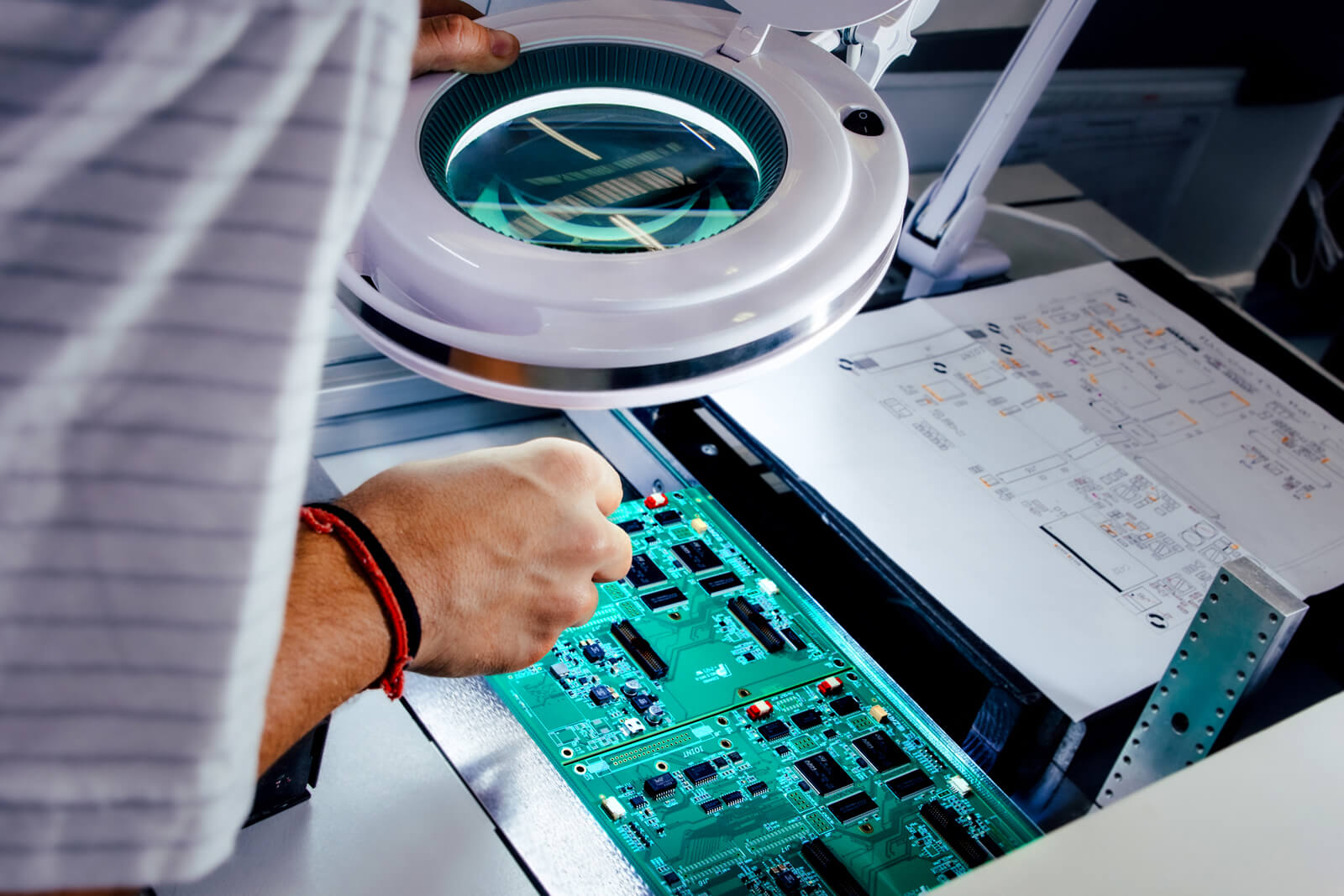

Quality assurance is our credo: Guaranteed throughout the production via visual inspections, automatic optical inspections (AOI) as well as functional tests.

We strive to consistently fulfill our promise of high quality, delivered on-time. Our production processes are not stagnant, instead they are continually tweaked in the name of optimization. The combination of modern machinery, the expertise of our experienced employees and our precise and solution-oriented way of working means we are able to uphold our quality standards with ease. If all of that hasn’t yet convinced you, we’re also able to produce small batches as well as complete series.

We are your partner for your electronic products.

Production process

At wtronic, the importance of traceability is well-known. Depending on the individual wishes of our customers, we adapt our traceability processes to observe the highest quality standards.

Included in our service is marking components by means of QR codes. Each individual component is given its own QR code which, when scanned, not only contains the information about the component itself, but the associated information from the manufacturer as well. Furthermore, the assemblies can be provided with serial numbers/QR codes/labels/lasers, depending on the customer’s requirements, to facilitate the assignment to production batches.

Whether you want each component to be marked individually or prefer marking the PCB as a whole, we can provide traceability adapted to your wishes.

This guarantees a transparent and reliable supply chain as well as optimized quality control for you, our valued customer. At wtronic, it is a point of pride to provide customers with the best of the best: Traceability, responsibility, and superb quality and commitment to ensuring your project launches without a hitch.

Individual labelling for top performance

The first step in our production employs the latest laser technology. Here, each PCB receives a custom label. Regardless of which format you desire – be it Data Matrix, Accord, letters or numbers – our high-tech laser ensures the label is placed with high precision.

Quality solder paste

With the aid of a stencil, the solder paste is applied to the PCB pads. An even application can be guaranteed by using a screen printer with support grid and optical paste monitoring.

Melting point for stable bonding

In the reflow process, we fuse the solder paste by means of individually adjustable temperature zones, depending on the precise melting point for any particular soldering paste. This creates firm bonds between the PCB and the component while avoiding common defects, such as tombstoning.

Control for highest quality

One approach to quality control we offer is the Automated Optical Inspection (AOI). The position, polarity, codes/numbers and the soldering quality of components is checked to ensure no visible defects are present.

Precision to the last cut

With a rotating knife we remove the individual PCBs from the production panel. This prevents damaging the circuit board or any of the components.

Quality made to measure

Finally, the individual function test takes place, during which we determine and document specific values. The test is tailor-made to ensure the PCB operates within the performance parameters set by you. With every PCB assembled, our production strives for perfection.

5. Mounting

Mounting

Mounting services for modules and complete units, including partial and pre-mounting are included in our broad range of services. Additionally, we may also take care of potting and material purchasing, if so desired.

Function tests, durability tests and final tests for finished units may be requested, as well.

Last but not least, we deliver the packaged product with all necessary documents, including the operating instructions, to an agreed-upon location.

- Mounting of modules and complete units

- Potting

- Material procurement available on request

- Function test, durability test and final test

- Packaging

6. Testing and inspecting

Testing procedures

Through a variety of specialized testing methods, the quality and reliability of SMT/THT assembled components and electronic units is ensured. In addition to standard test procedures, we develop test adapters with our partners in accordance with our customers’ requirements. Alternatively, providing your own testing equipment is possible as well.

7. Logistics

Storage, delivery and materials management

Modern logistics management and advanced traceability measures, tailored to each individual production phase, means nothing gets lost in transit. Our in-house courier connects all three locations on a daily basis – from our headquarters in Voelkermarkt to our state-of-the-art production facilities in northern Italy and Slovenia, and back.

This not only guarantees a secure supply chain, it also minimizes the dependence on postal services, nipping delays in the bud. The aim is to get your assemblies and products to you as efficiently as possible.

Thanks to our distribution warehouse we can boast with just-in-time deliveries. For maximum cost efficiency, we offer component stocking, materials management and Kanban deliveries as well as consignment stock.

wtronic’s strengths

Get in touch with us!

There are countless ideas, reliability and a lot of heart and soul in every technical product we create with and for our customers.

Founder